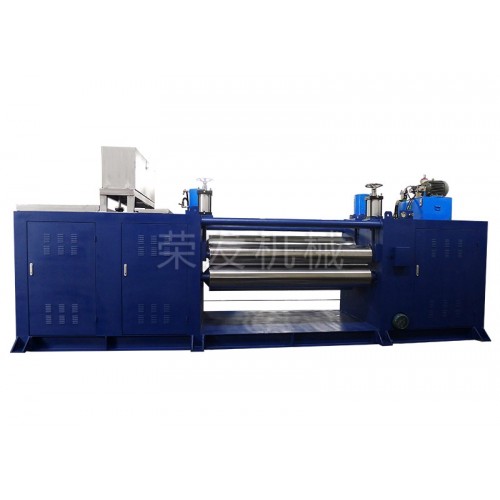

Fiber hot pressing machine: select high-quality steel (such as alloy steel), through many advanced production processes, so as to ensure smooth and precise products.

Application:

It is widely used in all kinds of non-woven fabric production lines to make the products flatten and set to the required thickness. It can also be matched with a flower shaft to make the product reach the required pattern.

Main Specifications:

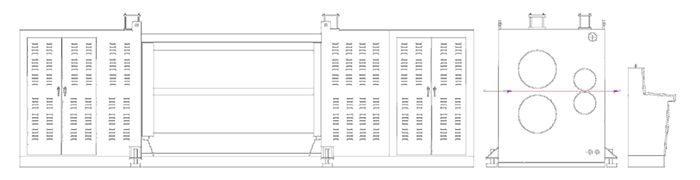

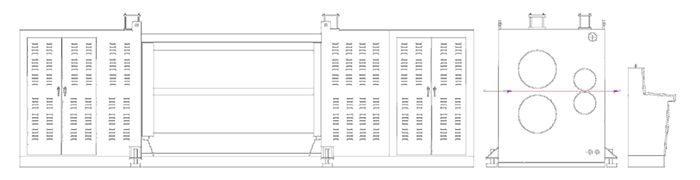

Model: two roll type

Shaft width: 1.5m-8m

Working temperature: normal temperature ~ 230 ℃

Temperature difference on shaft surface: ± 1 ℃

Roller radial runout: < 0.03mm

Line speed: 10-50m/min

Heat source: electric heating heat transfer oil

Structural Features:

The hot rolling part is mainly composed of hot rolling roller, chassis, main bearing, hydraulic lifting device, transmission device and controller. The hot roll is made of alloy steel seamless tube or 48crmoa seamless tube. After adjustment and machining, it is treated with medium frequency compound treatment. The hardness is more than HRC62 ° and the wall thickness is 50 mm Ф 300~ Ф 600mm, the thickness between the rollers is displayed digitally, the surface of the hot roll is treated by finishing, chrome plating, grinding, regrinding and polishing, and the finish of the roller surface reaches 9-12 grade (mirror). SCR automatic temperature control, digital display temperature, small temperature difference, water-cooled main bearing, long service life.

The cold rolling part is mainly composed of cold rolling roller, main bearing, cylinder lifting device, transmission device and controller. The cold rolling roller is made of alloy steel seamless tube or 48crmoa seamless tube. After adjustment and machining, it is treated with medium frequency compound treatment. The hardness is more than hrc620 degrees (no trace is left by the broken needle), the wall thickness is 25 mm, and the shaft diameter is 5 mm Ф 250~ Ф 400mm, drive frequency conversion adjustment, cold water cooling to achieve cooling stereotypes. The surface of the cold roll is polished by chrome plating and then ground. The finish of the roll surface is 9-12 (mirror surface).