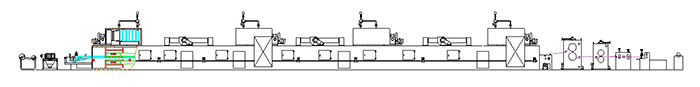

Application:

The Shoe Material Vertical Stretch Boarding Machine is used to produce carpet for gas vehicle, civil carpet, interior decoration for gas vehicle, shoe materials and various stretch forming products.

Main Specifications:

Product width: 1500-2600

Heating temperature: normal temperature ~ 220 ℃

Heat source: direct fired natural gas, plus heat transfer oil, heat exchange, plus hot air

Line speed: 5m ~ 20m / min

Heat consumption: 200000-400000 kcal / section

Product thickness: 1mm ~ 15mm

Main Features:

① Chain rail: Rongfa special vertical chain rail, vertical transmission mechanism, automatic stretching shaping.

② Edge detection: far infrared edge detection tracking ball screw adjustment, automatic needle on and off the needle.

③ Speed, width, temperature, humidity and air volume can be automatically controlled by man-machine interface.

④ High thermal efficiency, the temperature in the drying room can rise from normal temperature to 220 ℃ in half an hour.

Production Process:

Cloth Placement → Cloth Storage → Gluing, Back Gluing, Glue Spraying, Scraping and Dipping → Stretching and Setting → Hot Pressing and Ironing → Air Cooling → Cloth Storage → Slitting and Trimming → Automatic Cutting and Stacking → or Combined Winder